Whether you require gloveboxes, inert gas purification, solvent purification, or fully custom systems, Vacuum Atmospheres Company has the right solution for you and your team.

Our entire company shares in the vision of creating world-class inert atmosphere solutions for our customers. You can trust our team to deliver custom made products for your project’s requirements.

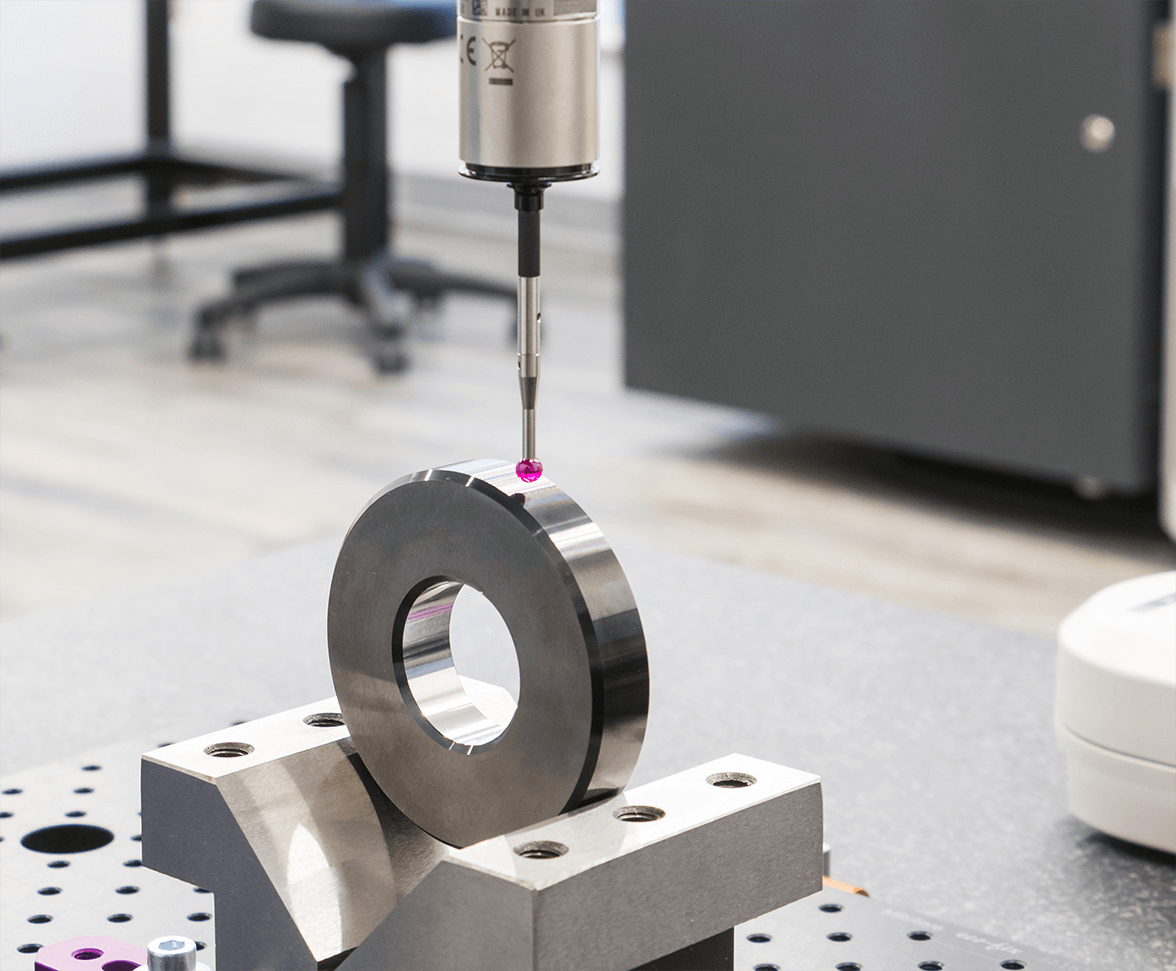

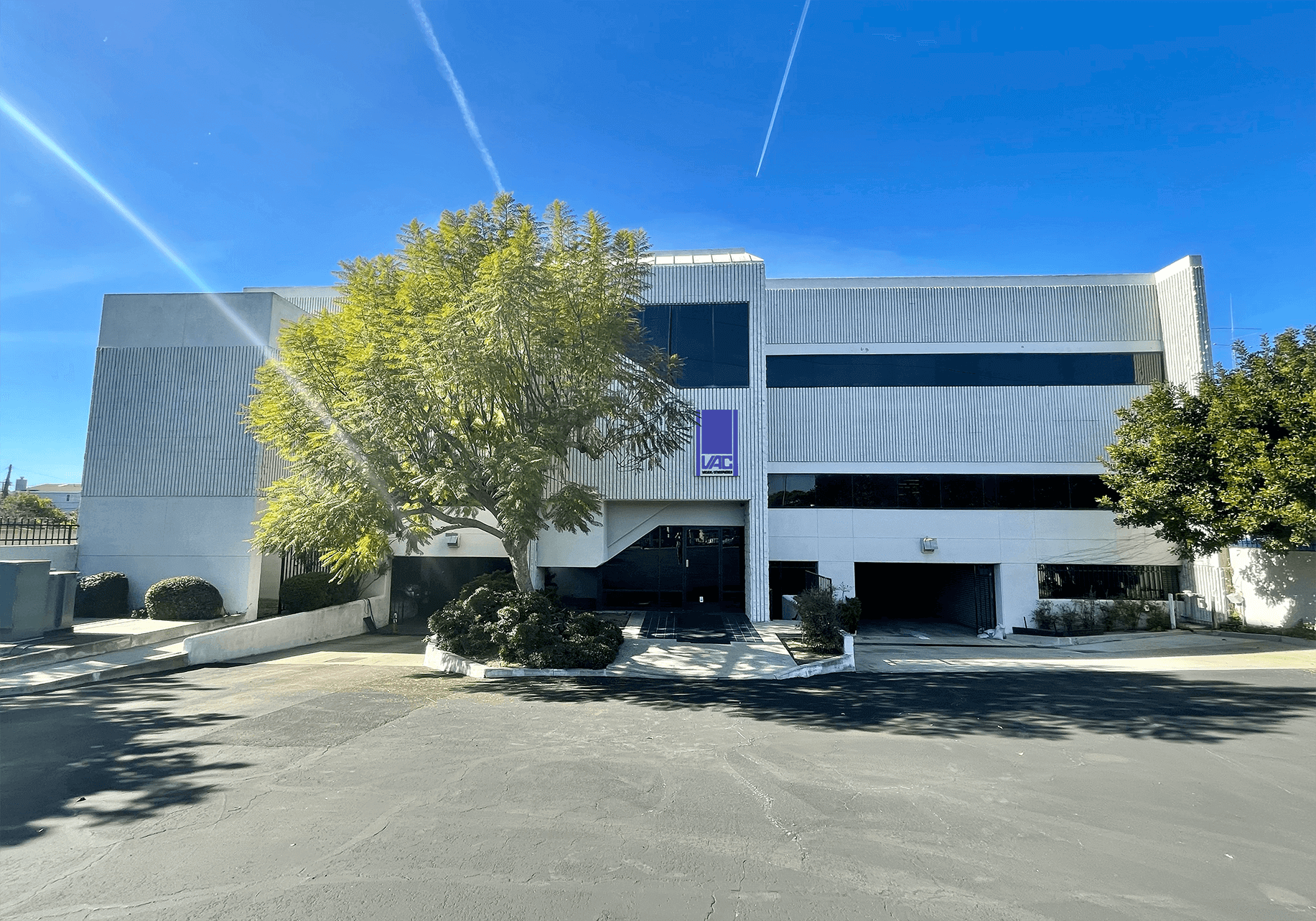

Every system is built in our 78,000 square foot facility located in the United States. Our complete in-house manufacturing capabilities allow us to assure maximum control of quality and scheduling.

Our highly experienced engineering and sales personnel are devoted to supplying you with personal assistance for system integration and product selection.