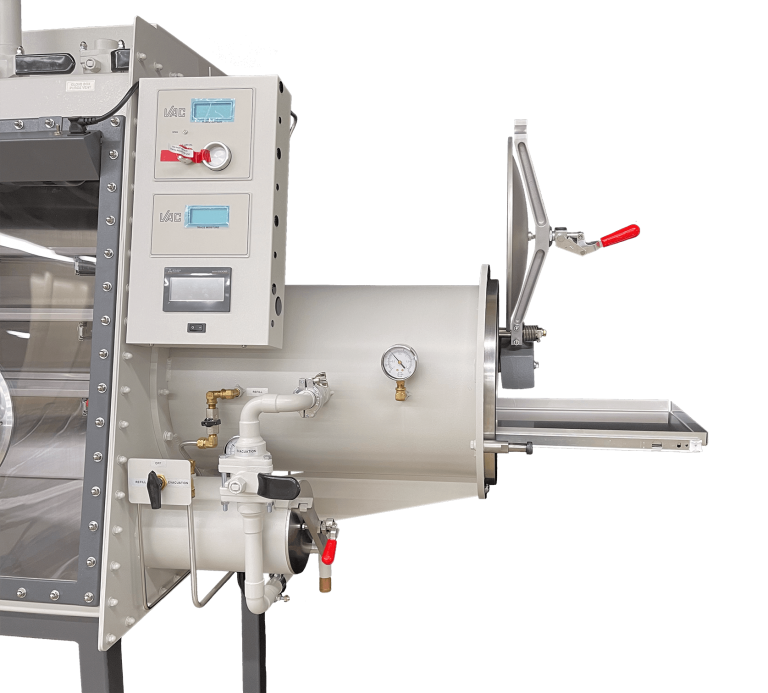

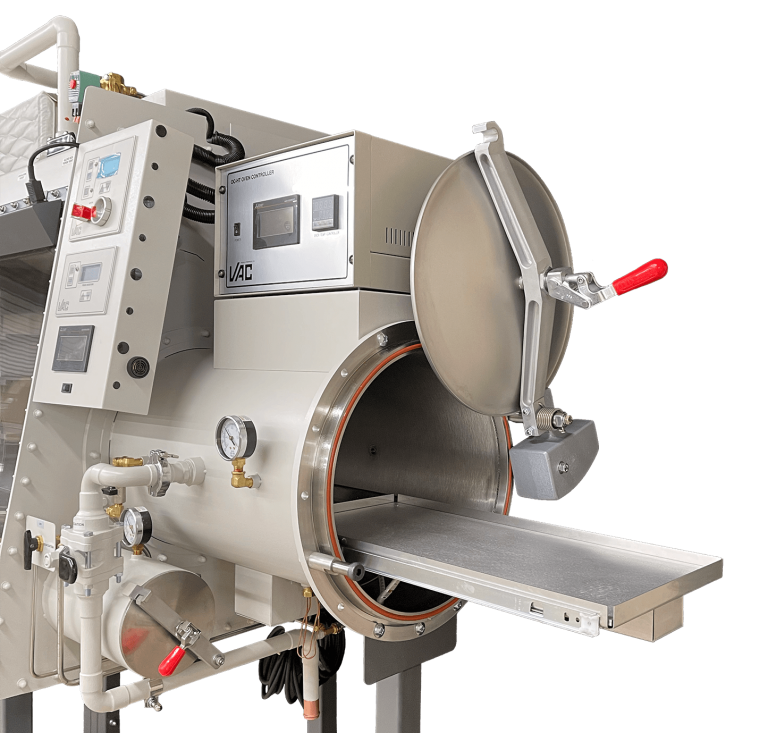

The OMNI-Lab Glovebox provides universities and commercial firms a cost-effective solution with full inert atmosphere performance and a user friendly control system.

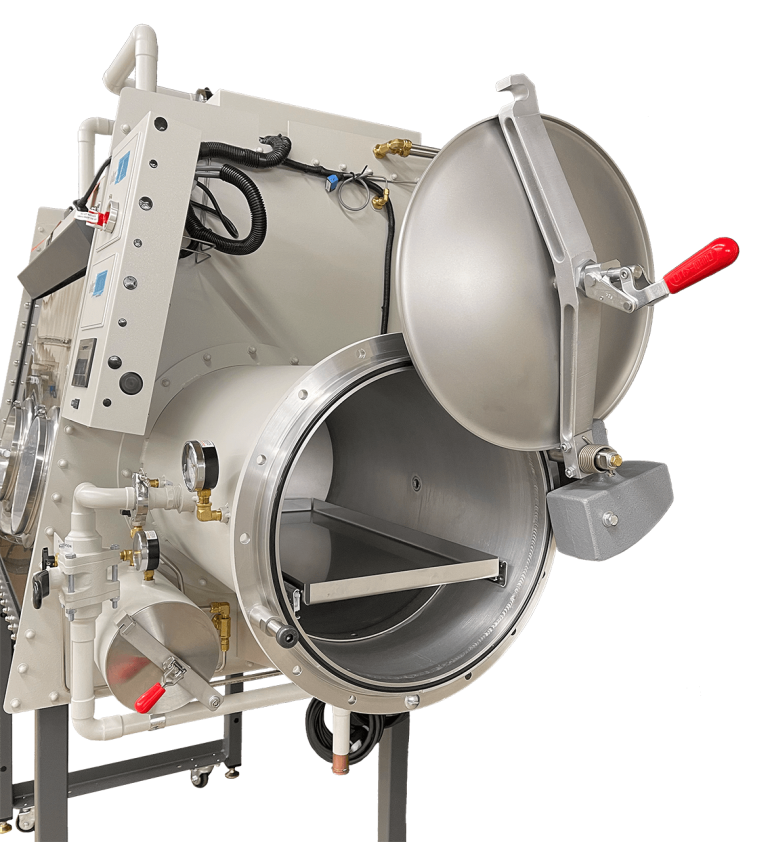

The manual circulation, antechamber, and purge valves provide easy one hand reliable operation.

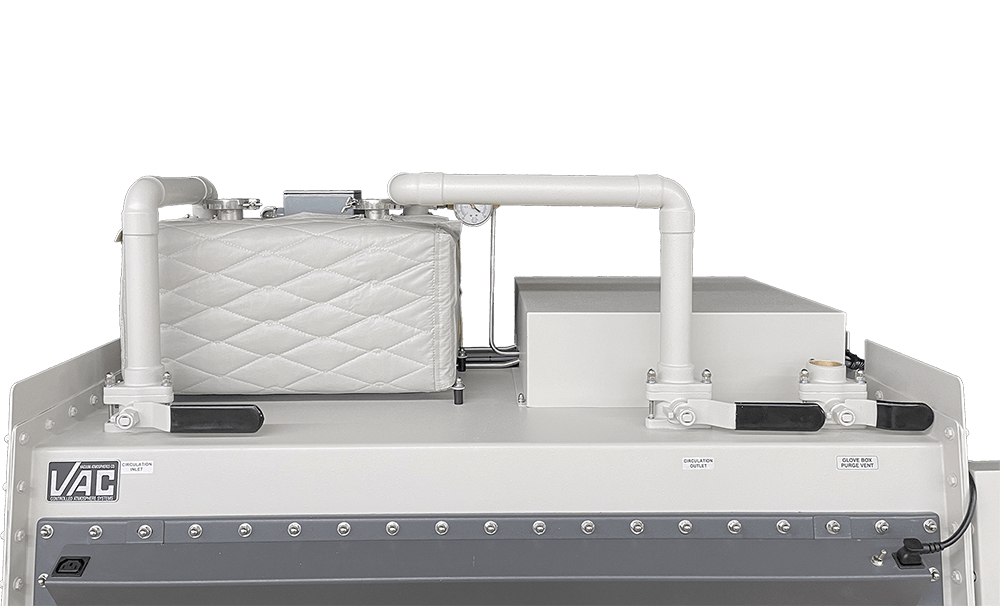

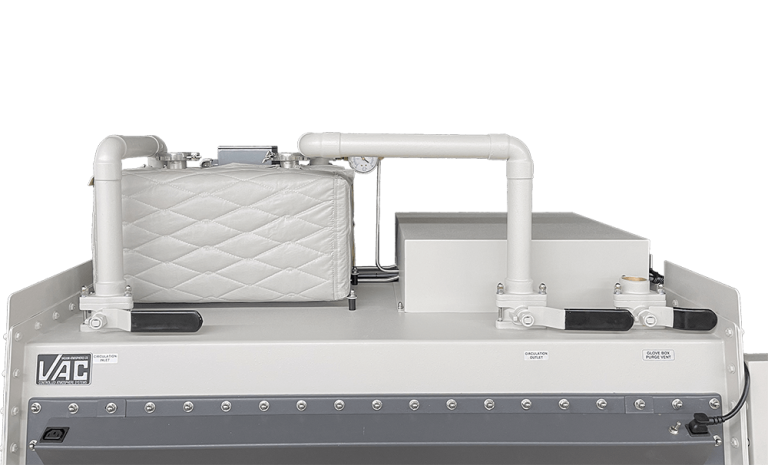

Since the Purifier is located on the top of the box, this allows the OMNI-Lab Glovebox to be the ideal platform for custom integrations of cold wells, spin coaters, special heating wells and other equipment installed on the glovebox floor required for your research.

Choosing the OMNI-Lab Glovebox means your precious laboratory space is preserved.